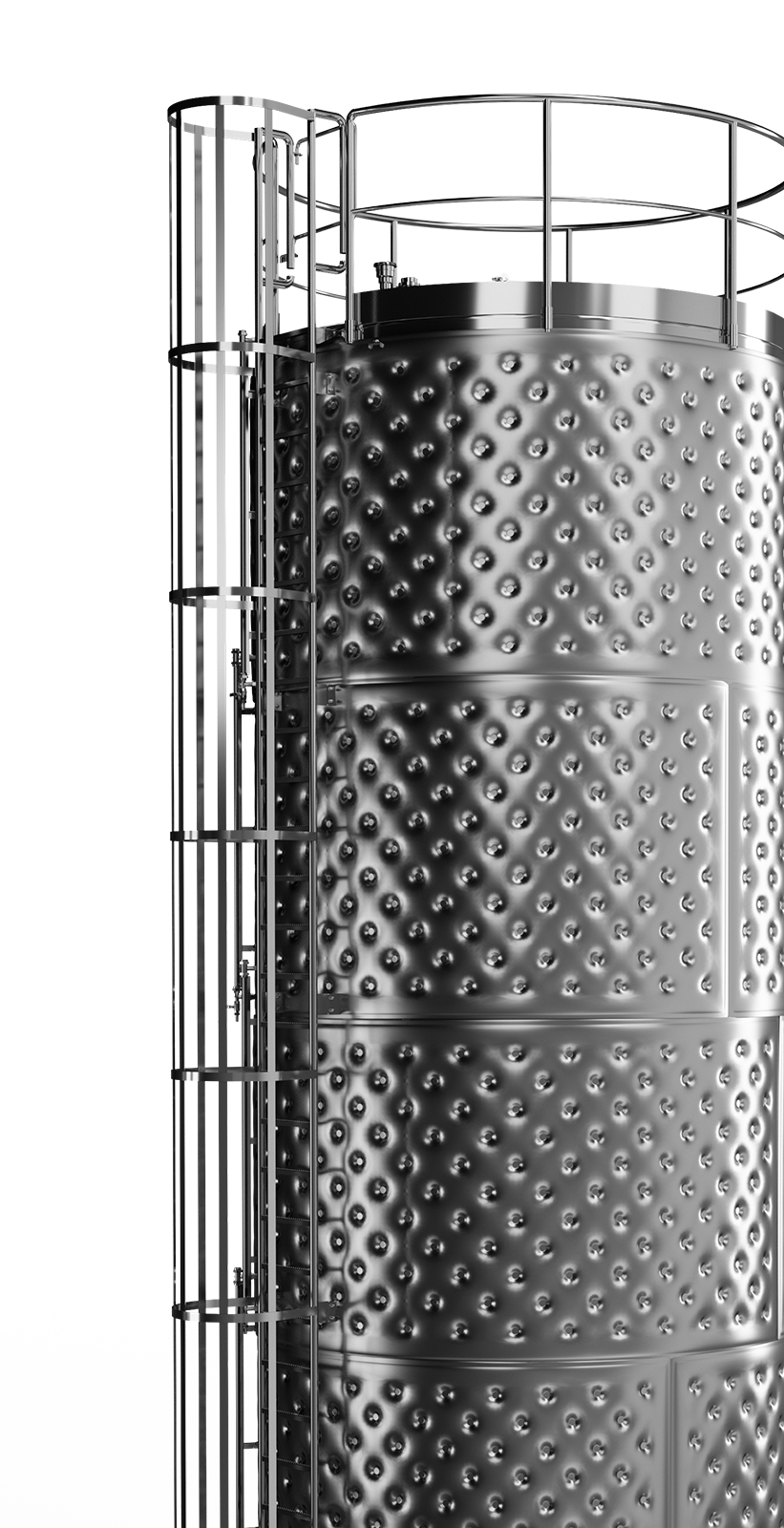

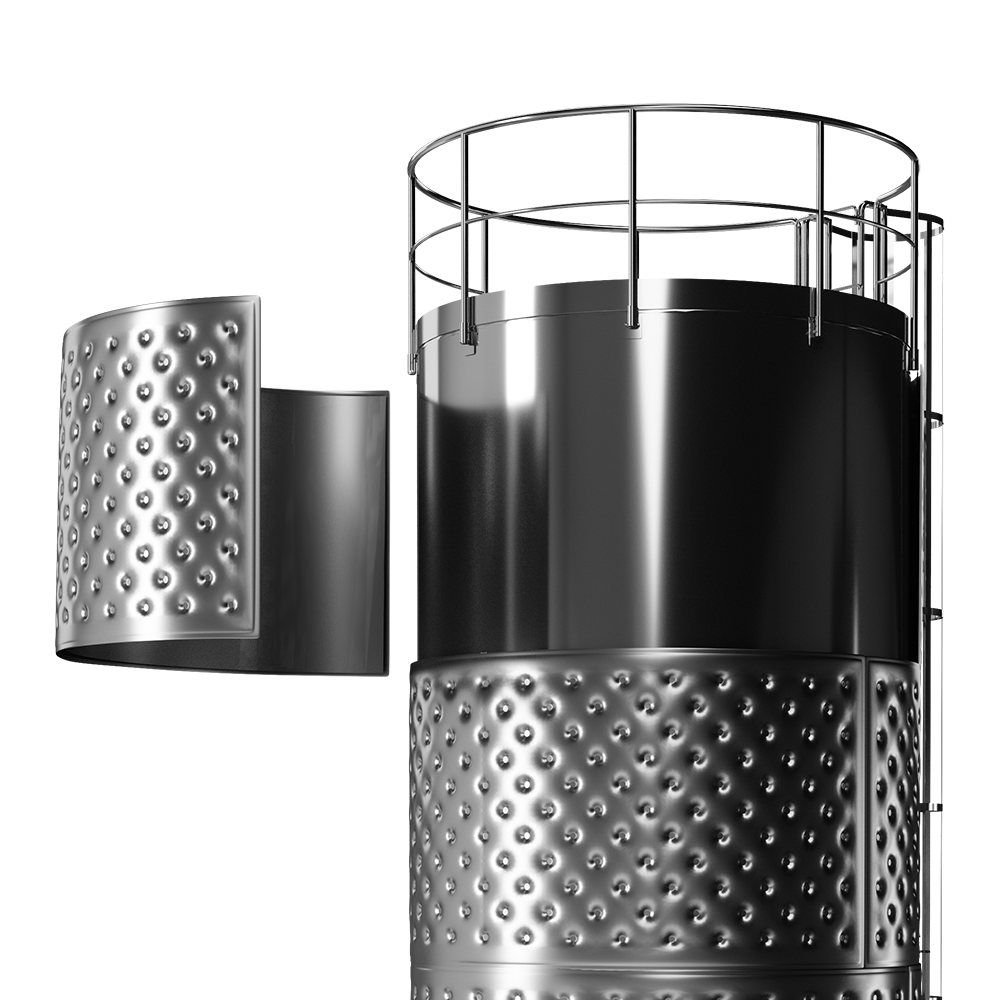

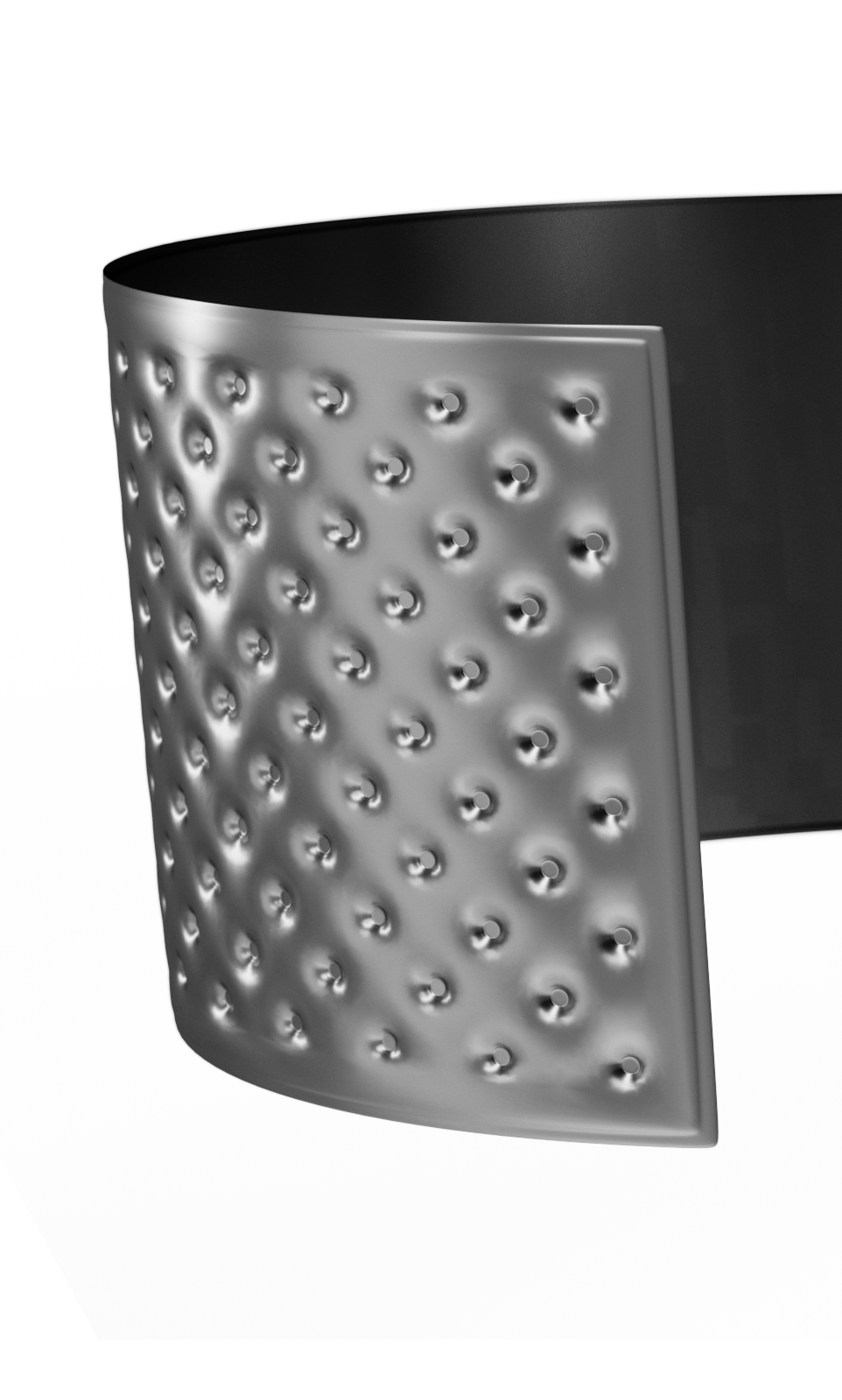

Pillow plates are economic and energy-efficient solution increasingly used in many different sectors of the economy.

Product engineering is considered as innovative but from year to year it gains more and more sympathisers. Using modern constructional solutions we can gain better heat exchange parameters, with the same parameters of thermal factor at the same time.

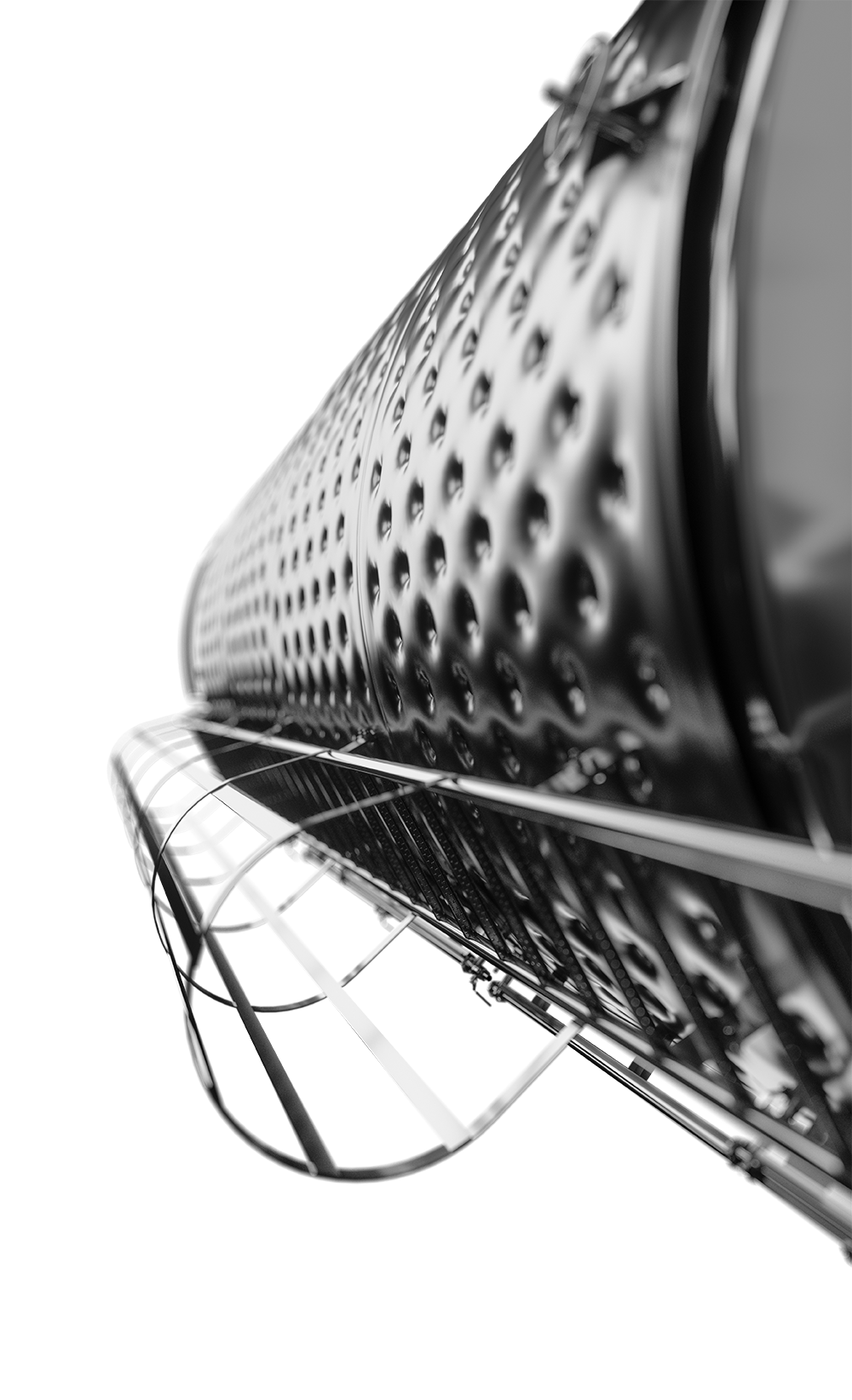

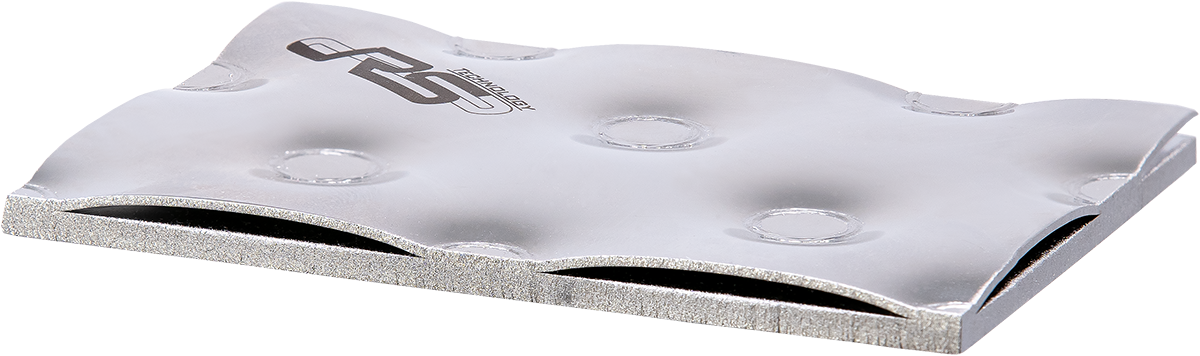

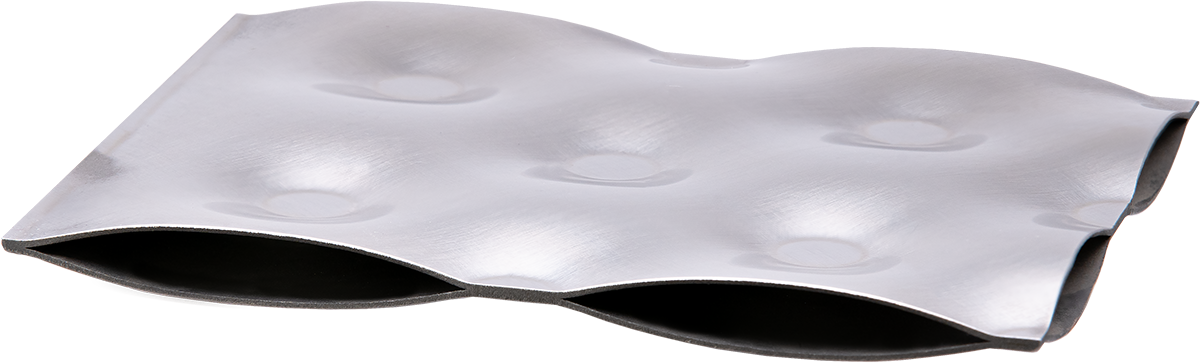

What is Pillow Plate?

Those are two sheets of inox metal, which are spot welded in a laser chamber. It can either heat or cool the liquid inside the tank.